Copenhagen, Denmark

Copenhagen, Denmark

Smart Port System at Stena Line

Stena Line’s new innovation, its rePORT system uses automatic tracking of incoming vehicles with license plate recognition, automatic weight measurement and more.

About the Client

Stena Line is one of the largest ferry operators in the world. It services Denmark, Germany, Ireland, Latvia, the Netherlands, Norway, Poland, Sweden and the United Kingdom, Stena Line is a major unit of Stena AB, itself a part of the Stena Sphere.

Quick Project Facts

- Locations: Karlskrona, Sweden

- Products: FreewayCAM, Carmen® ANPR Image, Globessey Data Server (GDS)

- Key functionality: vehicle analysis based on ANPR, weight and category

- Year of installation: 2019

At the Stena Line shipping port in Karlskrona, Sweden, there is a lot of goods coming through each day. A new project, called rePORT is being implemented to automate processes and make workflow smarter—in Stena Line’s vision there is a smart port system where freights are properly tracked and the personnel’s job is aided with smart technology.

Let’s Start With Some Math

3 or 4 ferries leave every day from the Stena Line shipping port in Karlskrona. Each ferry can hold from 300 to 500 trucks—that adds up to 1,000–2,000 trucks every day. Registering and analysing such a number of trucks implies huge resources—as we speak about several minutes per each truck.

What if we could ease this process with smart technology—and do this under seconds?

A New Concept With Smart Technology

Stena Line’s new concept called rePORT makes this possible, using a perfect mix of smart technology:

- License plate recognition

- Laser-based categorization

- Weight measurement

- CCTV surveillance and a complete database to manage all these incoming data.

Read below and figure out why these all are necessary.

The Challenge

Managing 1,000+ trucks every day and optimizing weight and ferry load capacity requires the following process:

- Each truck has to be registered at Stena Line—in advance, so all vehicles are expected and capacity is optimized based on this preliminary data.

- When the trucks arrive at the port, the vehicles have to be verified and their carriage has to be cross-checked with the pre-registered data.

- If there is a match, the access is granted and the truck can enter the ferry on a given lane.

The Solution: Smart Technologies, Integrated

We talk about multiple technologies that work seamlessly integrated into one smart port system. As mentioned, each vehicle has to be dentified and its carriage should be verified. Here is how it is implemented.

License Plate Recognition

A key pillar of this system is the tracking of vehicles’ license plates using Automatic Number Plate Recognition (ANPR) technology. Purpose-built ANPR cameras capture the license plates of each vehicle and transfer the images to the server where OCR algorithm extracts the number plates and turns image into digital data. This is how vehicles are identified and cross-checked with the pre-registered data.

Laser Categorization

Not only the license plates, but the carriages are also identified—using high-precision laser beam technology. This laser scans the shipment from multiple angle, providing a volume analysis. This volume is cross-checked with the preliminary input to verify the data.

Weight Measurement

In addition to the carriage volume, the weight of each truck is also registered using special weight-in-motion (WIM) system that is capable of measuring weight even of a moving vehicle.

CCTV Surveillance

The cameras do not just capture license plates but with a secondary lens a general CCTV photos are captured for security surveillance purposes. This way, the port has records about what happened at the gates and later these records can be searched in case of any investigation.

Complete Data Gathering Solution

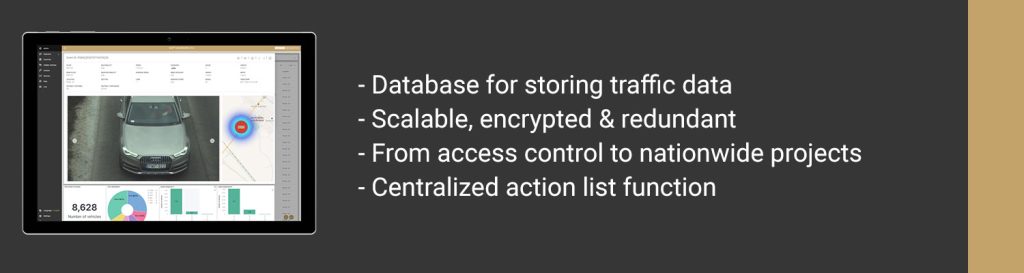

All these data inputs could not be managed without a complete software that groups these inputs and creates event data packages. This is implemented by the revolutionary Globessey Data Server (GDS) which is a perfect middleware between the data collection points and the port IT system.

GDS is a fully scalable data middleware solution that can be configured both for access control systems and the full highway system of even a whole country (like it works for example in Hungarian nation-wide toll control system – read the case study here).

Installation

One great advantage of such system is the—surprisingly—short installation time. Two experts within three days completed the local setup: by the 2nd day the system was already working seamlessly they had the last day only for testing and fine-tuning calibration.

Secondly, as this is a system with remote updating feature, there is no need to visit the site all the time when there is a system renewal, it is done within minutes (though we are happy to travel and see our clients any time!). The same feature lets the user always be aware about the health status of each endpoint – having an up-to-date information about the system working properly.

The Benefits

- Multi-modal verification in a single step of all incoming goods

- Automated ferry load capacity planning

- Smooth entry access, reduced to a few seconds from several minutes

- Multiple technologies packaged in one solution, no need for further integration

Though this project is only in a proof of concept phase, the results are quite promising—expect further updates shortly.